Source: The West Australian

More for Moore

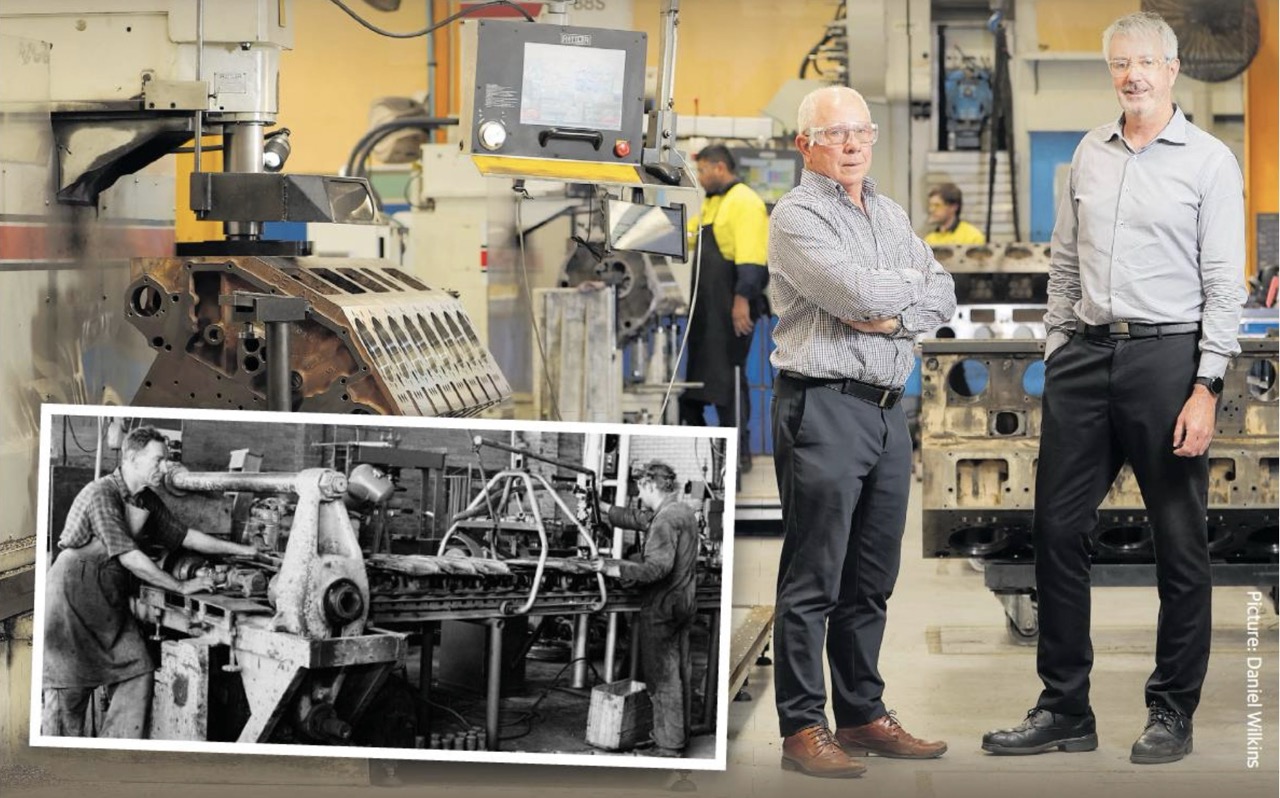

The boss of third-generation family business R. Moore & Sons credits keeping up with the latest technology advancements for its survival over more than a century.

The Perth-based engine components fixer — which is celebrating 103 years since the late Robert Moore, pictured below, opened a workshop behind the family home — said it always made a point to look towards the latest industry trends overseas.

This propped the business up during recessions and World War II, when there was continued demand for engine parts but few workshops having the expertise to provide high-quality products.

Over the decades, R. Moore & Sons has grown from a workshop on Short Street, Perth, to a purpose-built factory in Kewdale, where it is based now.

General manager Stuart Davis, pictured above right, said Robert did plenty of overseas travel to form international contacts and networks.

“It meant there was always a fresh look at industry trends and technology and what we needed to invest in to make sure we remained aligned and purposeful for what we’re supplying,” he said. “Getting outside of our own four walls and travelling has always been in the DNA of RMS.”

R. Moore & Sons — which specialises in inspecting, testing, servicing and restoring diesel engine components — counts clients in the mining, oil and gas, rail, defence and marine industries across Australia. It also has clients in Indonesia and Africa.

Robert’s grandson Warren, pictured above left, a company director, recalled starting from the bottom of the firm’s “food chain” in 1968.

As by family rules, his brother Neil, now also a director, began in the clerk’s office and Warren as an apprentice.“We’ve travelled an awful lot and we were always looking for opportunities, looking at technology from anywhere in the world and bringing it home,” Warren said. He said they made sure to travel every two years to places such as Cleveland, Ohio, Pittsburgh, Pennsylvania, Frankfurt, Germany, Italy and the UK.

The company continued to be adaptable when the pandemic hit, the same year it celebrated its centenary.

To ensure continued operations, Mr Davis said the company implemented a “lean” management, which he defined as a production process based on the idea of maximising productivity while simultaneously minimising waste within manufacturing.

“It focused on the workshop layout and being able to create that workflow in a very clean, tidy and process-driven environment,” he said. “It assisted us in enabling plenty of space between our workers. For many staff, it was sometimes an escape, it was a safe place to be because we knew we had the systems and protocols in place.”

R. Moore & Sons recently teamed with Perth-based technology firm COREIoT to digitise the Kewdale workshop, in what Mr Davis said was another example of RMS continuing to be innovative.

All of the company’s machines, more than 150 in number, now has a tablet sitting alongside it, enabling team members to see each scheduled job.

There is also a TV screen on the workshop floor where all jobs on each machinery are visible.

“When you’re investing in technology and machinery, your staff can see a future,” Mr Davis said.

“We have many of our exapprentices now in leadership and management positions.”

Mr Davis said R. Moore & Sons was gearing up for increased demand from the sectors they work with, driven by the push to a greener era.

“We firmly believe we are going to be more relevant than ever in the future for many decades,” he said.